Guide to mine demolition in Australia

Mine demolitions are particularly complex projects that must be completed in compliance with industry regulations, and with minimal disruption to any ongoing operations. With mounting legislation surrounding mine site safety and remediation, understanding how to prepare and execute a demolition plan effectively is more critical than ever.

Whether the demolition is part of a mine closure, major upgrade or expansion, specialist skills and knowledge are essential to a safe and efficient project. At Major Projects Group, we leverage over 40 years’ experience to deliver dismantling, decommissioning, demolition and asbestos and hazardous material removal services at mines throughout Australia.

Below, we explain the fundamental factors to consider for mine site demolition works. Read on to discover the strategies, expertise and protocols required to achieve a timely, cost-effective and reliable outcome.

What structures and assets on a mine site can be demolished

Typical structures that are demolished on mine sites include:

- Prefabricated structures, such as administrative buildings and local mining site offices, rest sheds for labour, site toilets and change rooms, crèches, labour camps for contract workmen, stores and warehouses;

- Conveyors;

- Conveyor belts;

- Train load out structures;

- Water tanks;

- Thickeners;

- Transfer stations;

- Surge bins;

- Control rooms;

- Ore bins;

- Ventilation fans;

- Substations;

- Columns;

- Clarifiers;

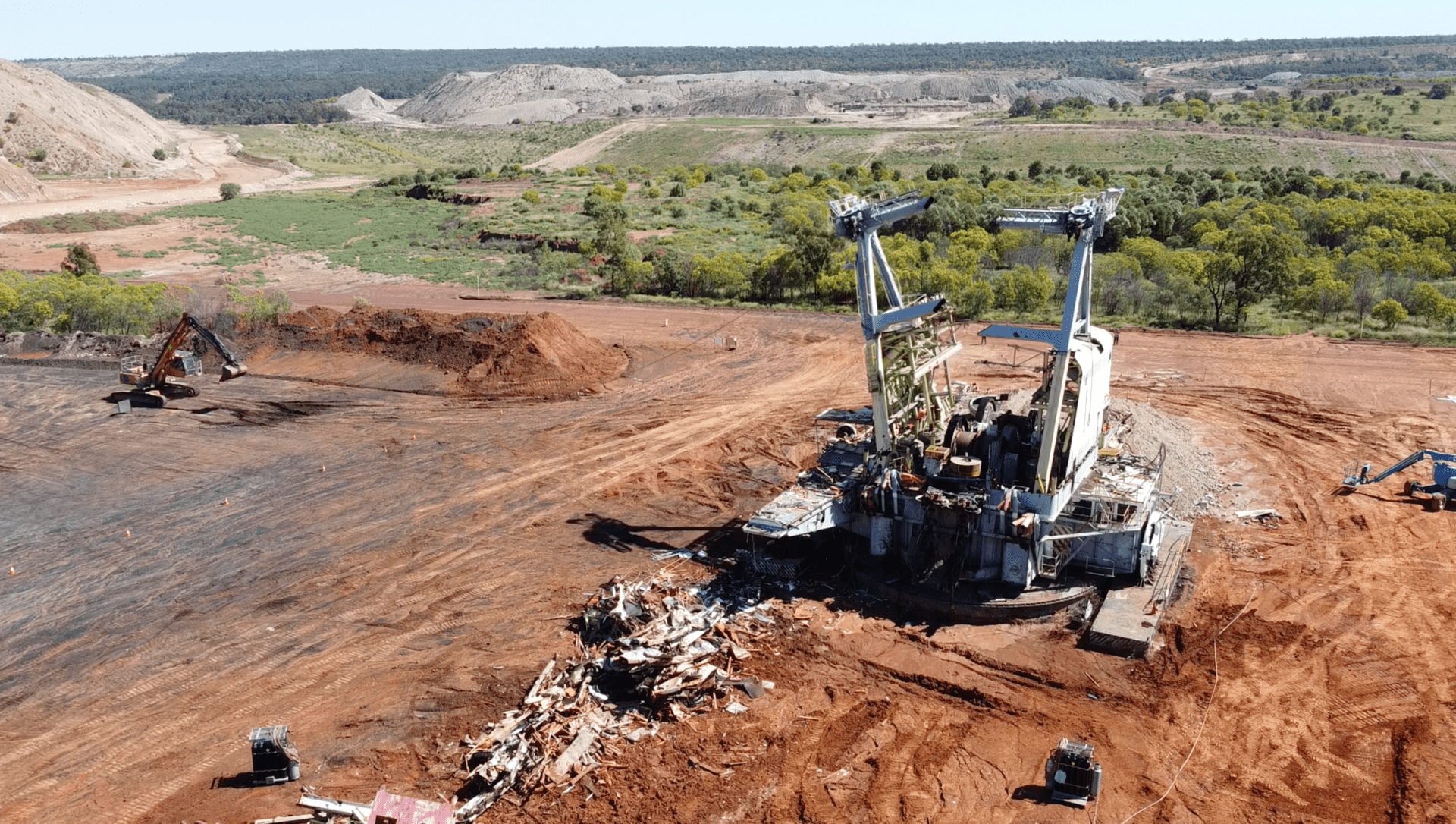

- Draglines;

- Rail lines;

- Chimneys/stacks;

- Boilers;

- Furnaces; and

- Reclaim tunnels.

Importantly, it is possible to salvage valuable assets, including hydraulic systems, switch room containers, conveyor pulleys and belts, during the demolition process.

How to find the right contractor for your mine demolition

Your mine demolition needs to be managed and executed by an experienced demolition contractor with industry-specific certifications and capabilities.

To ensure you engage the most qualified contractor for the project, ensure all companies undergo a strict prequalification process before being invited to tender. An increasing number of mine sites use online platforms such as Pegasus for this important step.

At a minimum, all mine demolition contractors should be able to demonstrate the following requirements:

- An unrestricted Demolition Licence;

- An unrestricted (Friable) Asbestos Licence;

- An ability to operate under the particular mines’ management system (if applicable);

- A certified Health, Safety, Environmental and

- Quality (HSEQ) management system;

- Plant and equipment approved specifically for mine sites (for example, in NSW, all mining equipment must undergo an MDG 15 assessment);

- A strong safety and environmental record;

- Proven expertise in all facets of mine-specific demolition; and

- All medical checks and mine site inductions required to mobilise personnel will or have already been actioned.

Preliminaries for mine demolition

Mine demolition demands a range of project-specific management plans to determine and detail the procedures necessary for a safe and successful outcome. These vital documents must be prepared in line with the contractor’s management system, client objectives and legislative requirements.

Below, we provide an overview of the primary management plans required for mine demolition. These strategies will be actioned though relevant processes and standard Operating Procedures (SOPs).

- The Demolition Work Plan identifies the most effective method of demolition, the project program and any potential risks to mitigate. It includes key information about the structure to be demolished, including its location, structural support system, and distance to surrounding buildings and streets.

- The Safe Work Method Statement (SWMS) is a legal requirement in Australia for any high-risk construction work, and therefore all mine demolitions. This document sets out every activity involved in the demolition, and the protocols implemented to mitigate associated risks.

- The Waste Management Plan (WMP) is of paramount importance for demolition projects on mine sites, where hazardous materials, such as asbestos, are often present. This document explains how all waste, including harmful substances, will be removed from the site before, during and after the demolition.

- The Environmental Management Plan (EMP) is another integral document for mine site demolitions, as it determines the practices that must be followed to minimise the project’s negative environmental and social impacts.

- The Health & Safety Management Plan (HSMP) features the precautions in place to protect personnel and the public from physical harm.

- The Industrial Relations Management Plan (IMP) is used to clarify the nature of communication and collaboration between contractor and client throughout the project.

- The Quality Management Plan (QMP) outlines the measures taken to support a high-quality outcome upon mine demolition completion, as agreed in the contract.

The relevant authority must also be notified of your intention to demolish the structure(s) on your mine site (and remove asbestos, if required). Notification regulations vary according to the state or territory. Discover more about demolition notifications in your region below:

Safety measures during the mine demolition process

Mine sites are dangerous environments before demolition even commences. As this destructive activity is being actioned in an already high-risk zone, it is of utmost importance to comply with all Health and Safety legislation throughout the project.

At Major Projects Group, safety is at the core of our culture. Our demolition-specific Health, Safety, Environmental and Quality (HSEQ) management system is grounded in decades of practical industry experience. Third-party certified for ‘Occupational Health & Safety’ (AS/NZS ISO 45001), you can trust in our commitment to protecting the general public, subcontractors, consultants, principal contractors and employees at all times.

To achieve this, our fully-licensed and insured team follows strict safety measures on award of every mine demolition contract. These include:

- Risk assessment workshops;

- Job Safety and Environment Analysis (JSEA);

- Mine site inductions;

- Take 5 procedure;

- Daily job start meetings; and

- Toolbox talks.

Learn more about each precautionary practice in our step-by-step guide to the demolition process.

Asbestos and hazardous material removal from mine sites

Site remediation strives to minimise exposure to asbestos and hazardous materials from contamination caused by mining activities. It involves excavating and encapsulating or removing contaminated soils from the mine site, along with non-recyclable waste, before the demolition takes place.

These processes are subject to stringent regulations pertaining to Occupational Health and Safety, environmental protection, waste management, public health concerns, building standards and mining operations. Furthermore, most states and territories have adopted the Safe Work Australia Code of Practice, which details protocols for the safe removal of contaminated soil.

Therefore, remediation for contaminated mine sites requires integrated expertise and a deep understanding of the wider Environmental and Waste Management Plans under which such tasks are performed.

With a Class A Friable Removal Asbestos Licence, Major Projects Group will ensure your hazardous materials and asbestos removal works are completed in a thorough and timely manner. Our mine demolition specialists partner with expert subcontractors to leverage unparalleled resources Australia wide.

Common methods of demolition on mine sites

Mine demolition can be achieved through several different techniques, the most effective of which will depend on the specific site conditions, project objectives and local environment.

Mechanical demolition

Mechanical demolition utilises machinery and manual tools, including bulldozers, excavators, skid steer loaders, boom lifts, telehandlers, generators and prime movers.

Wherever possible, Major Projects Group employs mechanical demolition methods to ensure adherence to the “As Low As Reasonably Practicable” (ALARP) model. This approach to risk management stresses the importance of minimising the number of personnel operating within the hazardous zone of a demolition site.

Major Projects Group introduced large-scale machinery to Australia’s demolition industry in 1997 after purchasing a 160-tonne excavator, complete with the world’s largest rotating shear. This groundbreaking equipment played a powerful role in the demolition of the Tioxide Chemical Plant in Tasmania.

However, it would be a further 12 years before any other companies realised the advantages of this approach, equipping our team with unrivalled mechanical demolition experience.

Today, we operate state-of-the-art plant and equipment across Australia, including a 250-tonne excavator with custom attachments. This investment in the most advanced and fuel-efficient fleet helps to accelerate your project while minimising our carbon footprint.

Explosive demolition

Explosive demolition is typically reserved for larger mining structures. As explosives must be positioned and timed with expert accuracy, this type of demolition can only be performed by a qualified professional with approval from a regulatory authority.

Depending on the amount of space surrounding it, a mining structure will be demolished so as to collapse inwards on itself or over to one side. If the latter approach is taken, steel cables will be attached to the structure’s side to ensure it falls in the intended direction. This prevents damage to any adjacent buildings, infrastructure or equipment.

At Major Projects Group, our skilled engineers and licensed shot firers are highly experienced in mitigating all hazards relating to explosive demolitions on mine sites.

High reach demolition

High-reach demolition is designed to dismantle tall structures surrounded by limited space and mines that require minimal disturbance to operations. It involves deconstructing the structure from top to bottom, a highly-precise process that results in significantly less debris than explosive demolition.

At Major Projects Group, we are equipped to tackle complex high-reach demolitions that include heavy mining infrastructure. Our high-reach fleet also works to minimise disruption to your operations by reducing the need for our team to interact with your workers.

Induced collapse demolition

With induced collapse demolition, integral structural supports are systematically dismantled to pre-weaken the building before it is subjected to a horizontal pull force that causes it to fall.

If several structural components must be removed together or the required force exceeds that achieved by machinery, Major Projects Group may utilise safe and efficient explosive methods to complete the controlled collapse.

Mine demolition contractors with a proven track record

Committed to excellence in mine demolition, Major Projects Group has been trusted to complete major projects for many of Australia’s industry leaders, including Glencore, Mach Energy Australia, Idemitsu, Rio Tinto and BHP Billiton.

Explore a selection of our mine demolition projects below:

A word on mine decommissioning after demolition

Once its structures have been demolished, the mine site should be left with stable landforms suitable for subsequent development and other productive uses. As well as minimising the impact of mining activities on our natural environment, mine decommissioning and rehabilitation serve to maximise the value of the site.

After disposing of all waste safely, remaining landforms, pipelines and structures will be assessed to ensure adequate stability for future use. Construction may take place at this stage, if necessary.

The next phase involves reviewing and monitoring the site to confirm that all project objectives and safety standards have been met. In certain cases, long-term maintenance may be required to ensure the mine has been decommissioned effectively.

Throughout this process, Major Projects Group follows the Code of Practice detailed in section 274 of the Work Health and Safety Act of 2011.

Enquire about mine demolition with Major Projects Group

With a myriad of procedures, technicalities and regulations to consider throughout a mine demolition project, engaging a reputable contractor with the expertise and experience to execute each stage is crucial to success.

A proud Social Enterprise championing environmental stewardship in the demolition industry, Major Projects Group utilises state-of-the-art equipment and certified HSEQ management systems to action the most complex industrial demolitions in Australia.

We provide an extensive range of capabilities, such as mine dismantling, decommissioning, demolition, asset recovery and asbestos and hazardous material removal, integrating safe, innovative and cost-effective solutions that meet all legislative requirements.

To commence your mine site demolition with Major Projects Group, enquire today on +61(0)2-4967-7900 or [email protected].